+919810069871

admin@rmalloys.com

RM ALLOYS is a customer driven organization that has made a commitment to supply products and services that will meet or exceed our customer's needs and expectations. The Directors of RM ALLOYS are into Aluminium business for the past two decades. Through the implementation of our quality system we strive to reduce costs while maintaining and improving our quality and competitiveness in the aluminium alloys marketplace. RM ALLOYS manufacture standard general purpose aluminium alloys, exhibiting an excellent combination of cost, strength, ductility, impact strength and finishing characteristics. We are the first choice when considering die casting.

Aluminium alloys are alloys of aluminium, often with copper, zinc, manganese, silicon, or magnesium. They are much lighter and more corrosion resistant than plain carbon steel, but not quite as corrosion resistant as pure aluminium.

Aluminium alloy compositions are registered with the Aluminium Association. Many organizations publish more specific standards for the manufacture of aluminium alloy, including the Society of Automotive Engineers standards organization, specifically its aerospace standards subgroups and the ASTM.

WE MANUFACTURE ALL KINDS OF ALUMINIUM INGOTS

RM ALLOYS has obtained test certificates to underline quality of its products. RM ALLOYS has obtained ISO 9001:2015. Certifications inspire confidence and trust.

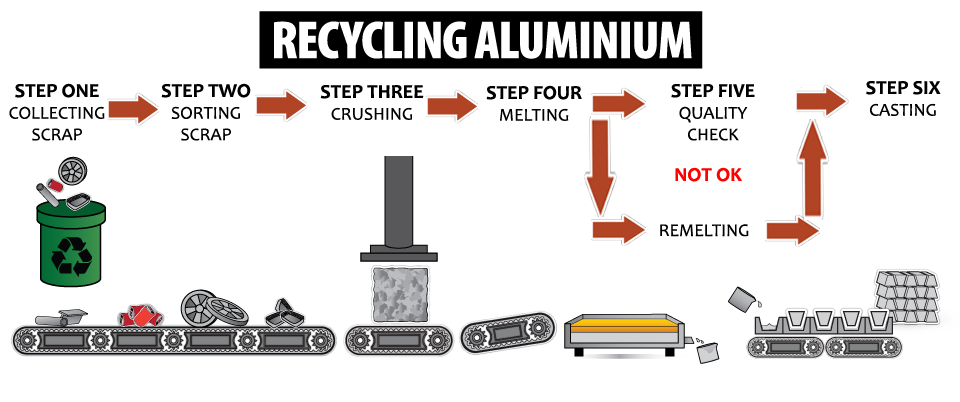

We are importing aproxx. 15000 MT of raw material majorly Aluminium scrap per year and manufacturing aproxx. 5000 MT of Aluminium ingot.

RM ALLOYS along offers Indian customers a wide range of world class Aluminum Alloys manufactured to the highest standards.

Contact Us

Spectrometer

K-Mould Analysis

Density of Alloys

Microscopic Analysis

Universal Testing Machine

Muffle Furnace

Viscosity Meter Analysis

Vacuum Analysis

RM ALLOYS become a benchmark company and a trendsetter for the aluminum recycling industry in supply of both solid/liquid products and contribute in the task of nation building to make India’s most industrialized nation in the 21st century.

RM ALLOYS will, over in the next Few years, expand its operations and to save millions tons of CO2 emission by recycling of aluminium scrape and to provide additional opportunities for companies to network across the waste and recycling industry.

Aluminium Recycling is an environment-friendly business as Aluminium is continuative recyclable and helps in conserving the resources available on earth. Compared to smelting, recycling consumes only 5% energy and produces only 8% gaseous emissions. Every ton of recycled Aluminium will save over 5 tons of bauxite, 1.2 tons of limestone and 22 tons of water, altogether consuming 95% less energy in production.

RM ALLOYS has made significant investments to introduce liquid metal supply in this industry. This has served as an effective method for emission reduction. Liquid metal supply eliminates the entire process of ingot melting by die-caster, which would otherwise lead to wastage of fuel and loss of metal.

All our plants are equipped with the latest pollution control systems which ensure under Suspended Particulate Matter (SPM) from our stacks, which far exceed the government norms for the recycling industry. Additionally, we continuously endeavour to deploy Energy Saving Technology.